Centerless Grinding

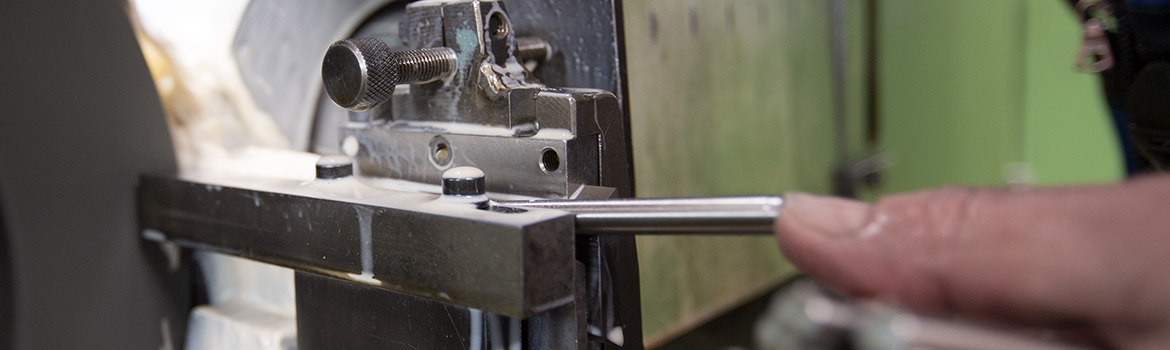

In centerless grinding, the work piece is not clamped, but placed on a wedge-shaped guide. Lying freely between the grinding disk and the control disk, which is slightly diagonal for forward propulsion, the work piece obtains a super finish. In addition, much more precise calibration is possible.

This finishing method for long and thin rods (we can handle diameters of 3-30 mm and lengths of 10-250 mm) makes it possible to adhere to specifications precisely, down to the hundredth of a millimeter.

Due to the absence of clamping, centerless grinding is relatively low-cost and enhances the parts' value.

The advantages of the permanently smooth surface, together with the dimensional accuracy, is appreciated by our customers with regard to piston rods, roller parts, guide tubes etc.

We will ensure that everything runs smoothly for you too – from the quote to the centerless-ground part. We look forward to your query!